The poor plasticity of bulk metallic glass (BMG) and its difficulty to shape is a dilemma in international non-crystalline material studies. Recently, under the guidance of his PhD advisor – Professor Zu Fangqiu, Zhang Qidong, a doctoral student from School of Material science and engineering made a major breakthrough in improving plasticity of bulk metallic glass by proposing a high rheological rate forming method to improve plasticity of BMG. The initial work of the study has been published on Materials Letters, and was highly appraised by Professor Johnson from California Institute of Technology, a big man in the industry of non-crystalline materials.

Metallic glass, or non-crystalline alloy, is a new material with excellent performance. Unlike common crystalline metallic metals, it has long-range disorder, thus possessing ultra high strength and hardness, great wear and erosion resistance, and soft magnetic property, which makes it a highly prospective new structural and functional material. However, its application in engineering is restricted by its brittleness, poor machinability and difficulty in thermal forming.

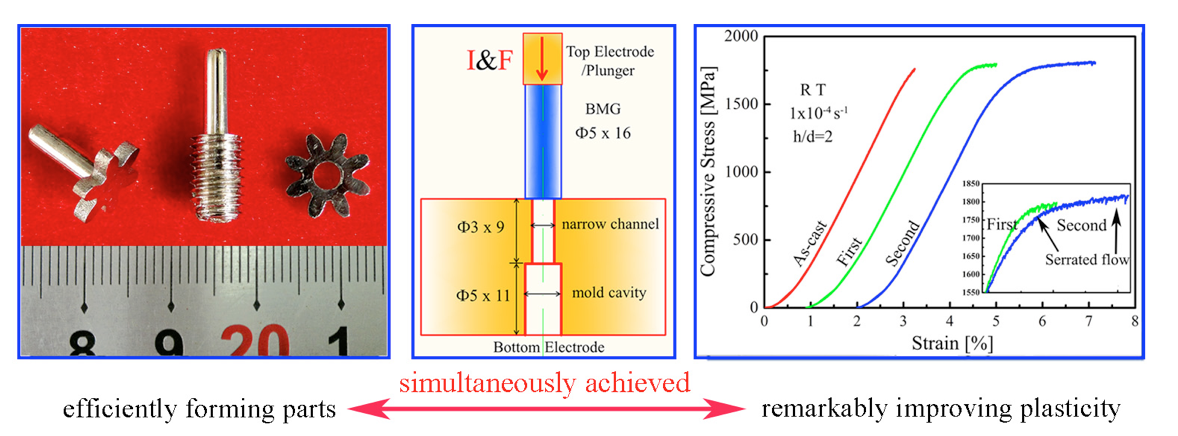

Based on the pulse heating technique invented by Professor Johnson, the team led by Professor Zu made innovations by adjusting the deformable ratio of the supercooled liquid and obtaining ultra-high rheological ratio, hence notably consolidating the heterogeneity of non-crystalline structures after forming. The high rheological rate forming method improving plasticity of metallic glass was thus developed.

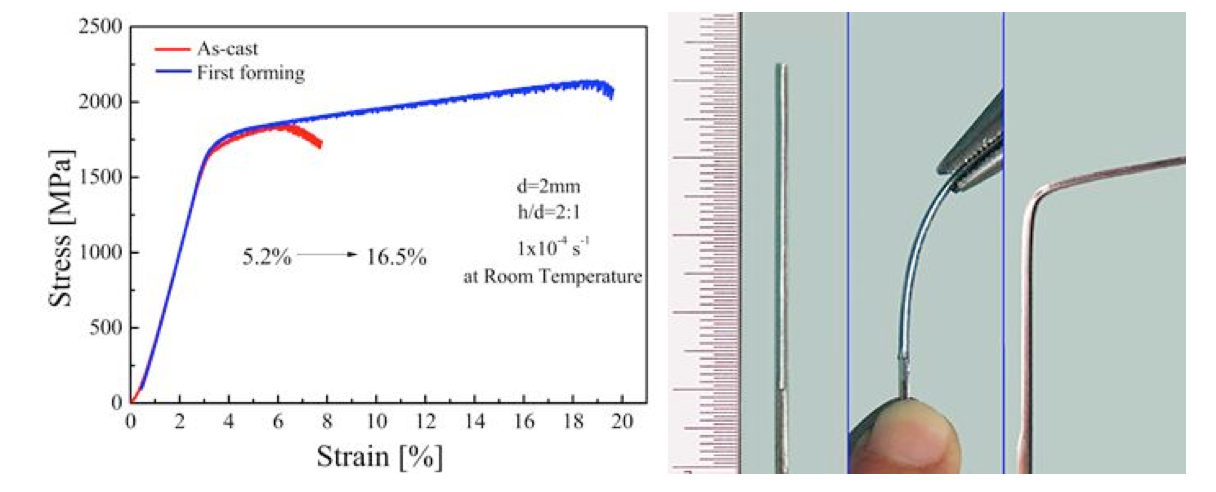

The enhancement of plasticity is attributed to the high microstructural heterogeneity induced by the inhomogeneous flow of supercooled liquid resulted from the high rheological rate.

The work is of great significance to the engineering application of BMG, and provides a new pathway for conveniently forming BMG parts with high plasticity in engineering applications.

Figure 1. The plasticity improvement and forming effect of HRRF on Zr48Cu36Al8Ag8 alloy

Figure 2. The effect of HRRF on other metallic glass

Access to the paper: http://www.sciencedirect.com/science/article/pii/S0167577X15308387

Written by & photo credit: Huang Zhongyue

Edited by: Zhou Hui

编辑:闵璇

HOME

/

Content

HOME

/

Content